How to Avoid Misleading Lumen Claims in LED Outdoor Lighting

—Judging “True Brightness” from an Engineering and Project Perspective

In the LED outdoor lighting market, “high lumens, high brightness” has become one of the most prominent selling points in almost all product advertising.

However, in real engineering projects and long-term operation scenarios, nominal lumens ≠ actual usable illuminance.

False or distorted lumen claims have become one of the most easily overlooked, yet most likely to cause problems later on, risk factors in municipal lighting, road lighting, industrial parks, and infrastructure projects.

For purchasers, contractors, EPC companies, and project managers, what truly matters is not “how many lumens are listed on the specifications sheet,” but rather:

Are these lumens real, stable, and capable of performing effectively in the actual environment over the long term?

This article will systematically analyze the reasons for false lumen claims in LED outdoor lighting from a professional engineering perspective and provide a set of executable, verifiable, and reusable judgment methods to help customers effectively mitigate risks during the selection phase.

I. Why is “False Lumen” Common in LED Outdoor Lighting?

In the field of outdoor lighting, lumens are not a simple number, but a comprehensive result highly dependent on test conditions, operating status, and system design. False lumens don’t necessarily stem from “malicious deception,” but more often from conceptual confusion and deviations in testing logic.

Common reasons mainly focus on the following aspects:

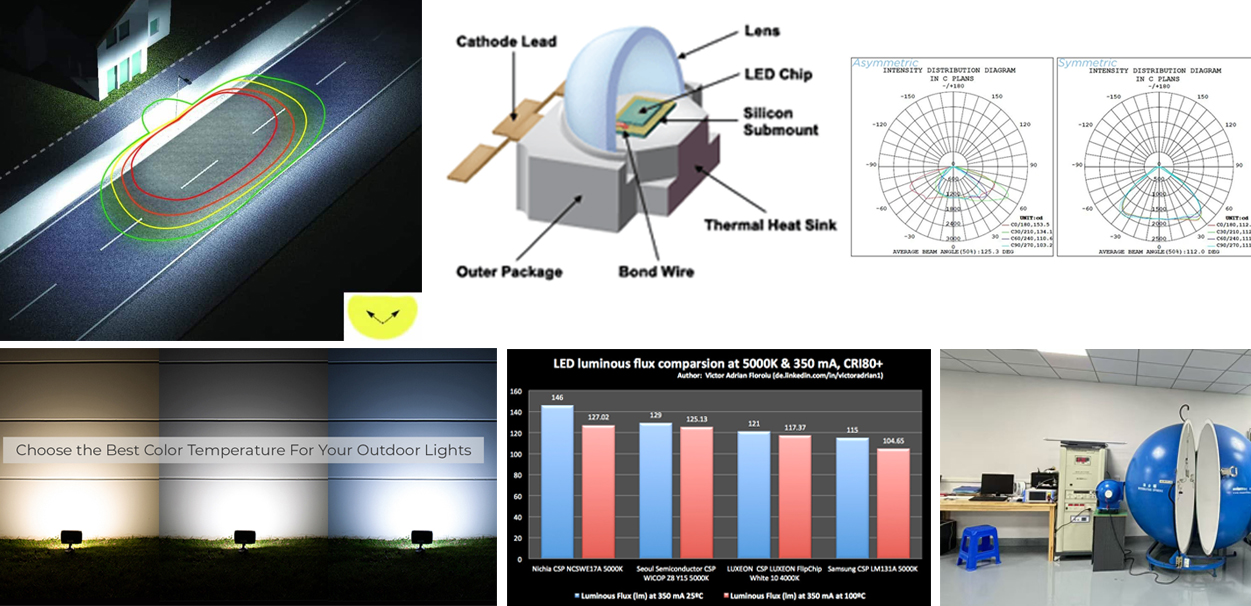

1️⃣ Only stating “LED chip theoretical lumens,” not the total luminaire output lumens

Some product advertisements use the maximum luminous flux of a single LED chip under ideal experimental conditions. However, in the complete luminaire, light loss, heat loss, and driver losses significantly reduce the final output.

Chip lumens ≠ Luminaire lumens

What engineering projects truly need is the effective luminaire lumen output.

2️⃣ Severe disconnect between the test environment and the actual usage environment

Common test conditions in laboratories include:

Ambient temperature 25℃

Short-term illumination

No long-term heat accumulation

However, the real outdoor environment is often:

40–55℃ high temperature

Continuous operation for 10–12 hours

Long-term heat accumulation in the lamp housing

At high temperatures, LED light decay and decreased driver efficiency are inevitable physical phenomena. If the lumen data does not take this into account, the value itself lacks engineering significance.

3️⃣ Neglecting Driver and System Efficiency

Even with high-efficiency chips, if:

Driver efficiency is low

The power supply operating range is unstable

The nominal power doesn’t match the actual power

The final light output will still show significant deviations.

Inflated lumen ratings are often not a “problem with the LED chips,” but rather a system design issue.

II. What real risks do false lumen ratings bring to engineering projects?

In the early stages of a project, false lumen ratings may only appear as “inflated figures on paper”;

However, after the project is operational, problems will gradually emerge, even directly affecting project acceptance and subsequent maintenance costs.

❌ 1. Insufficient illuminance, increasing acceptance risks

Road lighting, stadium lighting, and municipal projects often have clear requirements for:

Average illuminance

Uniformity

Glare control

If the actual output is lower than the design value, the remediation costs will be far higher than the initial selection costs.

❌ 2. Forced increase in power or denser lamp post spacing

To compensate for insufficient brightness, it is necessary to:

Increase the power of individual lamps

Shorten the distance between lamp posts

This directly increases overall investment and operating costs.

❌ 3. Rapid light decay later, leading to maintenance problems

Inflated lumen ratings are often accompanied by:

High junction temperature operation

Long-term full load on the driver

The result is:

Initially, it “looks very bright,” but after a year, it becomes noticeably dimmer.

III. How to Judge the Authenticity of Lumens from a Professional Perspective?

The following is a set of engineering-based judgment logic, suitable for procurement, technical personnel, and project managers during the selection phase.

✅ 1️⃣ Clearly Differentiate Between “Chip Lumens” and “Fixture Lumens”

Reliable product specifications should clearly indicate:

Total luminous flux (lm)

Testing standard (e.g., LM-79)

Testing institution or testing conditions description

If the specifications only show “LED chip luminous efficacy” without the overall fixture test results, be highly vigilant.

✅ 2️⃣ Demand Complete Optical and Photometric Data

Authentic lumens must correspond to:

Photometric distribution curve (IES file)

Illuminance simulation at the actual installation height

Lumen figures without photometric support have no engineering value.

✅ 3️⃣ Pay Attention to Temperature Rise and Long-Term Operating Conditions

Professional manufacturers usually provide:

High-temperature environment operating instructions (e.g., 45℃ / 55℃)

Temperature rise control design logic

Long-term aging test instructions

This directly relates to whether the lumens can be maintained long-term in a real environment.

✅ 4️⃣ Look at the System, Not Just a Single Parameter

To judge whether an outdoor lighting fixture has “authentic lumens,” you must look at it from a system perspective:

Is the heat dissipation structure reasonable?

Does the driver match the operating range?

Is the power real and stable?

Engineering lighting is never about “stacking parameters,” but about system balance.

IV. What Kind of Lumen Data is Trustworthy in Engineering Projects?

In actual projects, what is more trustworthy is not the “highest lumen,” but:

Sustainably output lumens

Stable lumens in high-temperature environments

Lumens consistent with photometric and illuminance results

For engineering projects, a real, stable, and slightly conservative lumen value is far more valuable than a seemingly impressive but inflated number.

V. Conclusion: Rationally Evaluating Lumens is a Sign of Mature Engineering Decision-Making

As LED outdoor lighting technology matures, the industry is shifting from “parameter competition” to “engineering reliability competition.”

Lumens are no longer just marketing numbers, but one of the fundamental conditions for the long-term stable operation of a project.

For procurement parties and engineering decision-makers, the truly important question remains:

Can this light fixture, in a real environment,

operate stably at the designed brightness for 3 years, 5 years, or even longer? When the evaluation criteria shift from “who writes the most impressive content” to “whose content can withstand scrutiny,”

false information naturally loses its ability to survive.